Working with brass : JAN GARNCAREK

I work in brass. I explore the possibility of bending, cutting, turning, tinting, soldering, welding involving various materials. I try to get the most beautiful things out of brass. I’m not afraid to experiment and I like to work with this material. I value traditional and old fashioned methods of working in brass. Due to this fact I can also support professions which are daying in Poland like drier or cutter. Nevertheless I also value working on my own with brass. Independent working with the material is necessary for conscious design. It is important to explore the full spectrum of the material and even go beyond conventional tasks. Experimenting with the material itself gives interesting possibilities and often leads the project in an unexpected direction. In my childhood I often soldered small brass objects. So I have long enjoyed the plasticity of this material. I also did various things from shells after ammunition. My family’s military traditions occured that such items were on a daily basis present at my home. In post-war Warsaw, brass was very rarely used in design.

That is why a return to pre-war traditions was something natural for me when it comes to design.

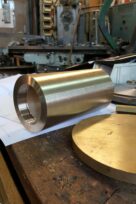

In my work I mainly use three types of machines. The basic one is a lathe and milling machine.

Working with these machines is not complicated. I use mainly their basic range of possibilities, slightly different than on the scraper. Scraper it is a third machine necessary to make the lamps of my authorship.In Europe, ther are very few specialists in manual spinning. There was a time that this technique was very popular for instance for production of various type of architectural decorations or kitchen equipment.

Currently, objects of this type are made on automated machines. Today, it is even more difficult to obtain material suitable for spinning. A special type of metal sheet that is still available needs to be warmed up to red, otherwise cracks will form easily. I am lucky that the workshop of the last brass spinner in Poland is located near to my family home. Thanks to friendly cooperation with the workshop I had a chance to learn many secrets of this craft.